30MHz is typing… Our extended support team is ready to chat!

At 30MHz we think it’s important that our users can use our platform in an optimal way. At times you may have questions and you would like some help from our support team. Email and our support page filled with helpful articles were your go to’s. But we thought it was time for something extra… That’s why 30MHz users can chat with us! Ask your questions directly to our Support team to get a quick answer.

- Chat available from 9.00 till 17.00 CEST (Dutch time)

- Ask us anything about our products and services

- Our new support team is ready to help you!

We aim to answer the chat as quickly as possible. Currently the chat function is available from 9.00 till 17.00 CEST (Dutch time). During other times of the day, it’s still possible to type your question in the chat, but then we answer your question by email. If your question needs a little research or there is a queue, then we’ll let you know so you’ll stay in the loop.

How to start a chat?

Two options: you can start a chat on the platform or on our website.

On the platform you see the Support button on the right side. When you click it the Live Chat opens. Just insert your name and email and start your chat!

On our website you can open the chat by clicking on the Support button on the down right of the screen. First you have the option to search for a subject and we make some article suggestions which might answer your question. Or you select chat. As soon as you send a chat message you will get confirmation when we’ve received your message.

What can you ask?

Anything regarding 30MHz! Think about questions about a specific sensor or granting a colleague access to one of your graphs. We will help you! Some cases will require input of our hardware or software department, or a third party. In that situation we will update you on the status of your request. If we need an expert we can agree to talk on the phone or send an email.

>> Answers to the frequently asked questions are also collected on our support page.

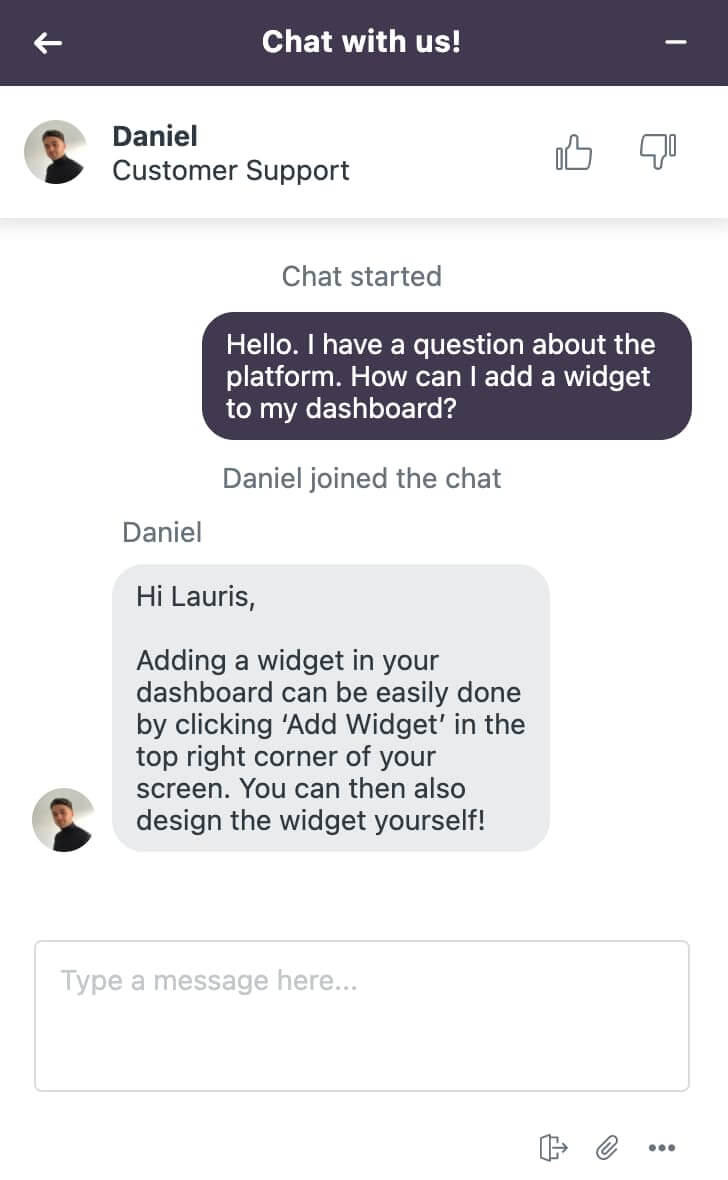

Example chat conversation with the 30MHz support team

Who are ready to help you?

Our support team is a mixture of experienced and new 30MHz colleagues. Everyone of them is determined to help you in the best possible way. Let’s meet!

Daniël: This student of business administration is eager to learn as much as possible about IT and entrepreneurship. When he’s not busy helping 30MHz questions he’s probably reading a book. As a regular visitor of the gym his favorite crop is obviously spinach. In the category of ornamentals he picks Rhododendron. “Just because of the name!”

Daniël: This student of business administration is eager to learn as much as possible about IT and entrepreneurship. When he’s not busy helping 30MHz questions he’s probably reading a book. As a regular visitor of the gym his favorite crop is obviously spinach. In the category of ornamentals he picks Rhododendron. “Just because of the name!”

Saladin: Claims he’s a real computer nerd and that seems to be pretty useful at a data platform. As a student of computer science he likes to do deep dives into technical questions and even sees this as his hobby! Saladin is interested in the digital revolution of horticulture. Broccoli, apples and orchids are his favorite crops.

Saladin: Claims he’s a real computer nerd and that seems to be pretty useful at a data platform. As a student of computer science he likes to do deep dives into technical questions and even sees this as his hobby! Saladin is interested in the digital revolution of horticulture. Broccoli, apples and orchids are his favorite crops.

Natasha: A real 30MHz expert. She’s been around our office since 2015 and knows our products inside out. Concerning crops, she’s really into peppers. But naturally she helps customers that grow other crops just as well. It’s important to Natasha that 30MHz users get the help they need on all our support channels. Happy users = happy Natasha!

Natasha: A real 30MHz expert. She’s been around our office since 2015 and knows our products inside out. Concerning crops, she’s really into peppers. But naturally she helps customers that grow other crops just as well. It’s important to Natasha that 30MHz users get the help they need on all our support channels. Happy users = happy Natasha!

Bauke: As a political science student he does not shy away from in depth analysis. We see this at 30MHz as well: no customer question is too tough for Bauke. Luckily for him a lot of customers are tomato growers, since he is a big fan of the red vegetable.

Looking for a new sensor?

Looking for a new sensor?

Designed for accuracy, flawless connectivity and remote placement, these tools are built to withstand the elements in all growing contexts. Build your digital infrastructure with a combination of sensors that suit your needs, and add new data sources at any time.

New 30MHz connect casing: How we protect your tech

To make sure your dataflow is fully protected, 30MHz introduces a new connect casing: waterproof, dust proof and even resistant to hits. This special shield will last longer and ensure a reliable dataflow from the connected sensor. What does that full protection mean? That’s what we will explain in this article.

New 30MHz casing: dust and water resistant.

Watertight: resistant to wetness

Moisture is daily practice in growing environments. If it’s an irrigation system or a humid chamber, you need to be sure that your technology is fully protected from wetness. Well, that’s the case with this casing.

We designed this model especially for usage in wet and unclean environments. Completely in line with the IP67 rating. Meaning that the casing can safely be immersed in 1 meter of water for up to 30 minutes. During our tests the casing was even waterproof for a minimum of 24 hours. So a big splash of water on or an accidental drop in a puddle: no problem for this casing!

Robust: resistant to hits

We optimise our product for the environments which they’re being used in. Moisture, radiation, changes in temperature: it all takes its toll on the material. This new casing is developed for many years of usage and protection from different climate conditions. A special ventil ensures a stable pressure inside the casing.

Of course it’s useful if your products can take a hit. Well, this casing is a true powerhouse. To make sure the technology on the inside is safe, we tried to break the casing during the test phase. We dropped a 0,5 kilogram ball of steel from a height of 1,3 meters on the casing. Both the material and the tech inside remained unharmed. So that’s proof that this casing knows how to take a hit!

Handy bracket for optimal signal

The casing can hang, stand or be attached to a wall.

Physical protection aside, it’s crucial that the signal is optimal. The data needs to flow smoothly from the sensor via the casing to the 30MHz platform. Sufficient mounting is important. We found something to help you with that: a universal mounting bracket. The special design helps you with mounting the casing and connected sensor in an easy and optimal way. Standing, hanging or attached to a wall, the bracket will help you mount the product in the way you see fit. After mounting you can start directly with collecting and analysing data on your dashboard.

Want to measure a different area every once in a while? No problem. The bracket is easily disassembled and replaced. Measure a different spot every week if you want!

All added up: more security for your tech

In conclusion, this new casing fully protects the technology from outside influences, so the data can flow undisturbed from your sensors to your dashboards. No worries about the performance of your technology, you can stay focussed on other tasks.

Want to know more?

Download the specifications of the connect casing:

Three insights from the table talk about data driven growing

Why is it important to have a connecting party when you are collecting data as a grower? And can you collect too much data? Just two of the many topics that were discussed during the table talk of TechnoHouse online tour hosted by Rijk Zwaan. Three experts joined a discussion about data driven growing and our commercial director Timo Spruijt was one of them! Let’s look back at three of the subjects that were covered.

(Scroll down if you prefer to see the video)

The experts:

- Timo Spruijt: commercial director 30MHz

- Mike Poodt: Digital Crop Technology Consultant at Rijk Zwaan

- Roy Persoon: Co-owner of MR Seeds

You need a connecter for the increasing amount of data

The last few years the amount of data has increased enormously and this will continue in the coming years. Every year hardware and software are becoming easier accessible for a larger group of growers. This urges the need for one central place, one platform where you can connect all your sensors. In that ever increasing field of data providers, you need a connector. A platform can be the link between all those data providers and data sources. A platform enables you to get the most out of your data.

Data is at its best when it moves around freely so users can decide which data they want to use to achieve their company goals. That’s why 30MHz focuses on connectivity and we make it able to integrate different parties into the same platform. This can help growers get a clear overview and turn that collected data into actionable insights.

Start digitising your cultivation process

The more you know, the better and faster you can respond to changing circumstances. The right data can help you optimise production efficiency, crop quality and operations.

The more you know, the better and faster you can respond to changing circumstances. The right data can help you optimise production efficiency, crop quality and operations.

30MHz Digital Connect provides you with the digital tools to create a database filled with meaningful and adequate data describing the status of climate and crop. You will be able to control and optimise growth plans and production processes in one digital platform.

Historical data can help for future decision making

The guests had a nice discussion about the question if there is something like too much data. A lot of data can be overwhelming, but to use data right you need to focus. 30MHz’s Timo: “If you are collecting data but don’t know exactly what to do with it, you can store it anyway. Then a few years later you can consult your database and connect it to the decision making process of that time so you know exactly what that data was for. Then you have a track record that you can use for future decision making. Technology will develop overtime. The need for data will grow. So if you already have a database of historical facts, you can make a better estimation of the impact of your decisions.”

Rijk Zwaan Researcher Mike Poodt pointed out that it’s important to make sure that the data you’re collecting has a certain quality. “If it’s not quality data, then you can store it but no one will ever use it. You can only create confusion for your colleagues in the future. Yes, we need to collect a lot of data, but always with an idea behind it.”

Roy Persoon of MR Seeds likes to build a database as a grower. “We are currently doing some measurements which we don’t really use. We are building a database anyway, because we expect that in the near future we can use it.”

Data belongs to the grower, and it’s important to keep it safe

Data used to be something you collected in your mind. Now it’s stored on computers and servers. At 30MHz we believe that data belongs to the grower. It contains valuable business information and you don’t want others to get your valuable information. At 30MHz we follow the international data security protocols to keep your data safe in our infrastructure. We secure your wireless network.

Click here for the recording of the event

Want to know more about data driven growing? If you have any questions about our products or want to know how we can help you take digital steps? Don’t hesitate to let us know! Email support@30mhz.com or fill in this form to get more information.

Creating a complete dataset in vertical farming solutions

Stacked growing beds full of leafy greens under artificial light and in a mesmerising mist. That’s the description of an indoor vertical farm at LettUs Grow. It’s their mission to bring the point of production closer to the point of consumption and enable anyone to grow food anywhere. This will reduce the waste and carbon footprint in fresh food production. With their vertical farming solutions they aim to boost the indoor farming industry. Analysing data is key to their mission.

Find a place in the food supply chain

Ricardo Lopes in an indoor vertical farm container.

Ricardo Lopes is a plant researcher for LettUs Grow. He started out in the greenhouse industry and switched to vertical farming. He saw that the last 5 years more and more people are starting to take the innovative approach of vertical farming more seriously. Ricardo is testing a large variety of crops in the LettUs Grow system.

A controlled environment

In such a controlled environment, Ricardo relies on various data sources. He needed a place where all these different sources come together, so he could do quick checks on climate data. LettUs Grow needed a platform to provide a realistic image of the climate inside the vertical farms.

“Where we need high quality climate data, we use 30MHz.”

“We had a good data set for what the farm was doing, but reliable and constant climate data was something we didn’t have at the beginning. Now we have everything. We can check data back to the minute in the 30MHz platform. It’s useful to see the fluctuation during tests with different levels of temperature and humidity, for instance. The 30MHz platform is a visual way of spotting any problems or spotting if something did go wrong. It made it a lot easier.”

Horticulture is more and more dependent on data

For LettUs Grow it’s all about optimisation of the controlled environment. To optimise it they need a lot of data and a reliable perception of what is happening inside the vertical farms. “That’s only possible when you have decent sensors and all your data in a digital place”, says Ricardo. “Horticulture is more and more dependent on data and what data tells us.”

LettUs Grow and Ricardo are optimistic that vertical horticulture will find its place in the food supply chain. “Maybe not next year, but maybe in 5-10 years we can deliver a decent amount of fresh produce worldwide. Not replacing another system, but complementary. Especially in big cities.”

Pointed Micro Climate sensor

This sensor uses leaf temperature and temperature humidity measurements to continuously capture microclimate at close range. Use data from the sensor to better determine heating needs, cutting unnecessary energy expenditures and lowering the risk of plant fungus and disease.

A lot of our customers use this sensor for measuring VPD and dew point.

Maximise growing rates, minimise the environmental impact

LettUs Grow provides technology for vertical farms and greenhouses. The British company combines indoor farm management software with their own aeroponics technology. In their soil-less system the plant roots are suspended in a nutrient rich mist. It’s a recirculating system which makes it resource efficient. Because of the controlled environment there is no use for pesticides. The system is created to maximise growing rates, while minimising the environmental impact.

LettUs Grow and Ricardo are optimistic that vertical farming will find its place in the food supply chain. “Maybe not next year, but maybe in 5-10 years we’ll be able to supply a significant amount of fresh products worldwide. Not replacing any other system, but complementary. Especially in large cities.”

Crop consultant: Remote advice is direct and future proof

The single greatest benefit from crop consultancy at a distance? Leo van Uffelen has no doubt: It’s the speed. The crop consultant believes that remote advice is the future in horticulture. Convincing the sector can be tough. But Leo has a weapon: data.

Subscribe to our newsletter to read more stories like this

Leo works as an independent crop consultant who’s specialized in pot plants. He sees that remote crop consultancy is on the rise. However most of the growers keep being sceptical. Especially the older generation, says Leo, who emphasizes that he is part of this generation.

“Even if I provide evidence and make sure the plants are ready for delivery in time, they cling on to their old methods. Understandably, because they always relied on their feelings while growing. We didn’t have real time data back then. It’s easier to convince the younger generation. Nowadays, we have the tools. So we have to use it. We are able to grow without relying on feelings.”

Consulting at a distance makes a better advice

Leo is in the middle of his weekly visiting round when we talk to him. Once a week he walks through his clients greenhouses to see if the data corresponds with how the crops really look. Just to make sure that the plants are ready for the next stop in the supply chain.

He says that consulting at a distance simply makes his advice better. It’s a big contrast compared to his old methods.

“Back then, I also made my weekly rounds”, Leo tells us. “If I noticed some bleaching in the leaves, I advised to use the screens differently. During my next visit a week later the bleaching disappeared, but a new problem occurred. The screening caused a decrease in light, which led to a slower growing pace. Nowadays, I’m not depending on that weekly visit anymore. I can always check the current climate settings of the greenhouse.”

The big advantage is that he doesn’t have to be on location to provide tailored advice. It makes consultancy faster. It is crucial that his data loads directly, emphasizes the crop consultant: “As soon as I have data, I can consult. No data, no advice.”

Monitor crop-level and climate insights in one platform

Do you want to work towards a greater understanding of what your crops are doing rather than what the climate around your crops is doing?

Do you want to work towards a greater understanding of what your crops are doing rather than what the climate around your crops is doing?

30MHz Digital Complete combines macro and micro climate data and uses measurements directly from your crops to monitor their health. We can connect your climate computer and various crop-level sensors to your private wireless network and feed all your data into your account within our platform.

Download the information about Digital Complete

Instant analyzing the climate settings

“The data gets imported real time into the 30MHz platform. As soon as measurements are outside of the setted limits, I receive an alarm. Then I log into the system, check the climate settings and analyse what’s going on. Next I take a screenshot and send a message to the grower. That’s how quick and direct crop consultancy at a distance is.”

On the 30MHz platform Leo created various dashboards to keep track of data flows. Like PAR, leaf temperature and vapour pressure deficit (VPD). From his own home he scans these dashboards. On his weekly round he uses the dashboards to substantiate possible points of improvement for his clients.

The value of these dashboards reaches further. He uses them to locate limits. An example: “I keep up on the amount of light a plant gets before the leaves start to yellow. The sum of light can be huge and that leads to a stronger plant. The crucial thing is to prevent the peak in lightning. These peaks can cause yellowing. I use the PAR sensor to measure such peaks. By adjusting your screen settings you can flatten the peaks and still reach the desired PAR sum.

More information about the lightning peaks? Leo shared his tips for a PAR dashboard.

30MHz Sensor Catalogue

Designed for accuracy, flawless connectivity and remote placement, these tools are built to withstand the elements in all growing contexts. Build your digital infrastructure with a combination of sensors that suit your needs, and add new data sources at any time. Our wireless sensors are made specifically for the needs of modern horticulture.

Designed for accuracy, flawless connectivity and remote placement, these tools are built to withstand the elements in all growing contexts. Build your digital infrastructure with a combination of sensors that suit your needs, and add new data sources at any time. Our wireless sensors are made specifically for the needs of modern horticulture.

All sensors arrive pre-configured and ready to deploy out of the box.

Download the 30MHz Sensor Catalogue

The future of a crop consultant?

In conclusion, the digital tools for consultancy at a distance are available. Leo uses a data platform and sensors. Will his advice soon be completely remote? “I will keep doing my weekly rounds. The importance of seeing the plants with the bear eye will stay. Because sometimes there are circumstances that require extra attention. Like a heatwave or a frosty week. In horticulture you can experience extreme days. So no surveillance at all won’t work for me.”

Leo van Uffelen uses the 30MHz dataplatform for his remote crop consultancy. Do you want to move forward in digitisation? Or do you have any questions? We are happy to help you. Let us know how we can help you: support@30mhz.com

Enjoyed this article? There is more where this came from! Subscribe to our newsletter and get our best stories directly in you mailbox.

Rijk Zwaan online event: How to use data in growing decisions

We are really happy to announce that we will participate in an online event organised by Rijk Zwaan. On the 27th of May, 30MHz will join a table discussion about Data Driven Growing. Together with two other data experts, we will talk in English about using data to optimise growing strategies. Interested about the use of technology in horticulture? Register now to join the event!

International plant breeding company Rijk Zwaan is hosting a series of online table talks with experts to show the use of technology in horticulture. The next edition is all about data. How can you collect data and use it to optimise your business decisions? That’s one of the many questions that will be discussed. As the data platform for horticulture, where are looking forward to join this discussion! We’d love to share the benefits of using data in a growing environment. The event is accessible for anyone interested. No matter if you’re a student or an experienced grower, there will be something to learn for everybody.

A sneak peek of what you can expect by our product owner Mirjam Bekker: “Data in itself is interesting, but what you really need are actionable insights based on your data. That way data becomes information.”

Check out the teaser ⬇

A breeder, a grower and a data specialist

Joining 30MHz during this discussion, will be grower Maikel van den Berg, co-owner of MR Seeds and a frontrunner in the area of data driven growing. He believes that in 5 years time, most of the greenhouses are being controlled autonomous. Mike Poodt is the other expert. He is a consultant digital crop technology at Rijk Zwaan. Mike will share his insights, based on his years of experience in breeding technology. The table talk will be lead by presenter Milou Turpijn.

Send in your pitch and present your idea

Do you have a related business idea that you would like to test? After the table discussion with the three experts, there will be an interactive part where three members of the audience can present their plan and receive live feedback. All you have to do is pitch your idea when you register for the event. Rijk Zwaan will select three submissions that will be presented and discussed during the event. So is you have an idea about horticulture data that you would like to pitch to experts, don’t hesitate to register and submit your plan!

We hope to see you at 27 May! Don’t forget to register, so you don’t forget or miss any updates.

When? 27 May, 16.00 till 17.30 CEST, the table talk is in English

Click here to register at the Rijk Zwaan website

Psst, while you’re here… We like to write stories about digital horticulture. Subscribe to our newsletter and get our best articles directly in you mailbox.

How Brabant Plant grows more valuable data

Brabant Plant connected their climate computer to the 30MHz platform early 2020. This led to valuable benefits. Cultivation researcher Marvin Verkuijlen tells us about his experiences with the integration. “Now it’s easier to compare different compartments.”

Brabant Plant is a Dutch family business that focuses on breeding young vegetable plants and pot plants. Apart from being an enormous nursery, the company has a research and development department. This is where Marvin Verkuijlen spends his days. He loves to use innovations and it’s his job to connect the dots between theory and practice.

“Data is something we discuss a lot at Brabant Plant”, says Marvin. “I have many colleagues with decades of experience. They are able to spot data fluctuations with their bare eyes. As a researcher I discuss these observations with them. I look at the plant from a physiological point of view and I combine my knowledge with our in house experience. That’s valuable teamwork.”

Marvin checking his dashboards.

Connecting your climate computer

Various data sources help Marvin to gather information. For example he analyses data regarding the use of different screens in the greenhouse. “This is a big company with lots of different compartments. I can use my Priva climate computer to check upon the climate situation in a specific area, but it doesn’t allow me to make a quick comparison to a different area.”

About a year ago Marvin connected the climate computer to 30MHz. This means all the data the climate computer gathers, is transferred to the platform. “And with 30MHz’s platform I can overlay data from various compartments. This makes it easy to compare compartments.”

Data pool with usable information

Marvin uses the Pointed Micro Climate sensor to measure the difference between the climate above and under the screens. “We place one sensor on a high point in the greenhouse, the other one on plant level. We also use this method for comparisons within a compartment, like comparing the left side to the right side. This creates a data pool with usable information”, says Marvin.

As a grower that focuses on young plants, Brabant Plant has a concrete floor. This is a big difference compared to growers with big tomato or pepper plants, because much more sunlight reaches the bottom of the greenhouse. At Brabant Plant they monitor the floor conditions carefully. Marvin: “Do we have to change the screen settings? Do we have to adjust the cooling settings? These are questions that you can answer by monitoring your data.”

Via Klimlink huge amounts of data can be integrated into the 30MHz platform. “The setup was easily realised. If you think about the amount of data that is being imported, I’m surprised how smoothly it runs”, says Marvin. “All sensors are easily recognisable in the system. I especially like the way you can visualise your data in dashboards. And additional sensors can easily be added to the platform.”

The Pointed Micro Climate sensor at Brabant Plant

Store and connect horticulture data

As a researcher in horticulture, Marvin expects data will get more valuable over time. “Data has alway been collected in horticulture. It gives you a guideline for a specific moment. But if you store and connect all that data, you can discover interesting things. You can create a map and track how a plant disease moves through your company, to name an example.”

“30MHz are a bunch of connectors. Together with partners they find ways to connect data. The challenge is to create one huge data pool where all sensors and data sources come together. If you can connect your planning, climate data, scout data and your IPM-strategy on a platform, you create valuable insights for your whole business.”

The integration of your Climate Computer or other third party data sources into the 30MHz platform is available within our packages Digital Climate and Digital Complete.

Want to know more about connecting your climate computer to the 30MHz platform? Feel free to ask us anything: support@30mhz.com

Enjoyed this article? There is more where this came from! Subscribe to our newsletter and get our best stories directly in you mailbox.

Growing cucumbers based on facts instead of assumptions

Drenthe Growers has been using Delphy’s Climate Profiler and Quality Monitoring System (QMS) since december 2019. They use these instruments to grow cucumbers based on facts. Green fingers are essential, but the grower is in need of extra certainty.

This is a summarised translation of an article that appeared in Magazine DE Delphy.

Peter Bergsma is the right person to experiment with digital innovations. The co-owner of Drenthe Growers has a technical background and had no experience in growing cucumbers until a few years ago. This allows him to have a fresh outlook on his work. Traditionally growers use their gut feeling. But if you keep track of all your data it’s easy to see how you have handled situations in the past. This can prevent problems. Growing gets more predictable.’

Bergsma participates in two Delphy pilots: QMS cucumber and the Climate Profiler. He uses the QMS to plan the yield. Every week he entries data into the system, the QMS calculates the planning and Bergsma adapts his strategy accordingly. ‘This helps me get a better understanding of the plant. The influence of the climate on the plants can be seen in detail.’

Climate Profiler helps you decide

Drenthe Growers also uses the Climate Profiler to help the planning. This application generates climate and weather data like CO2 levels, the light sum, temperature development and moisture levels. The grower describes an example: ‘You can calculate which temperature you need during certain light conditions. This creates a profile. Next you decide yourself how you want to realise these conditions.’

Bergsma also gathers data about leaf splitting and crop growth that he inserts into the application. Delphy advisor Rens Smith shares his feedback on a daily basis. ‘Rens visits once a week, but thanks to this system he can provide advice every day of the week’, says Bergsma. ‘We are expanding in the near future. We will use QMS and the Climate Profiler to control each greenhouse separately. This helps us in our planning and logistics.’

Always data at your disposal

Advisor Rens Smith is an early adopter of digitisation. ‘I can see the growers’ data before I visit them, so I arrive fully prepared. My conversations with growers get more value. We can go more in depth’, explains Smith.

The Climate Profiler is a step in the direction of data driven growing. Seeing how every greenhouse or location responds to climate circumstances is a huge advantage. This enables the grower to set up a slightly different growing strategy in every location to get the optimal results. The Climate Profiler calculates everything.

Rens Smith: ‘Sometimes we miss certain information in cucumber cultivation. The advantage of more data is that you can base your decisions on facts instead of assumptions.’

The Delphy Climate Profiler is an application hosted on the 30MHz platform. Within this application, knowledge of Delphy is translated into an application that provides real-time cultivation advice. Do you want to get more out of your data? Let us know! support@30mhz.com

2Grow app and 30MHz offer detailed plant insights to grow smarter

Biotechnology company 2Grow and 30MHz have joined forces to develop smart data tools that provide growers, breeders and researchers with even more detailed insights into the health and needs of their plants. This year they developed a new application: 2Grow Plant Insights. The app is available for free on the 30MHz platform.

2Grow offers sensors that collect data about the sap flow and stem diameter of plants. 30MHz and 2Grow have been collaborating on sensor technologies since 2019 and users of the 30MHz platform can easily connect 2Grow sensors to their dashboards. 2Grow Plant Insights now also provides them with additional, detailed information on the various ways their plant is being influenced.

“The 2Grow application gives you a better understanding of what exactly is happening with your plant, without having to use all kinds of formulas,” explains 30MHz account manager Tim Busschops. “It is an all-in-one solution: a data visualisation to make the information easy to digest, a combination of various data sources and consultancy, as you can see how your plant responds in real time. This is making the user wiser.”

2Grows sap flow sensor.

The growers stays in control

“Thanks to the direct feedback from the plant, we can generate many insights”, says Olivier Begerem of 2Grow. “For example, we can see the specific time when problems like blossom end rot and ruptured fruits have occurred. Based on this information we can anticipate to prevent certain problems in the future. By connecting the 2Grow sensors to the 30MHz platform you can combine other sensor and climate data with our measurements. This gives us the opportunity to draw conclusions much faster and our advice becomes more accurate.”

By consulting the measurements 2Grow can give advice on methods to make the plant more resistant to diseases. This information gets saved in the database for future reference. If you search for a specific temperature, you can see the advice that was given for that situation in the past. For example; when it’s a hot week in July, you can search the database for the advice that was given during a similar hot week the year before.

“Our platform offers more and more tools for the grower”, says Tim Busschops from 30MHz. “As a grower you stay in control. You decide which data sources and apps you want to use to optimise and improve your results.”

2Grow and 30MHz connect people and plants

The 2Grow app on the 30MHz platform.

Growers and breeders have a great need for information. On the 30MHz platform users can combine 2Grows measurements with information from other data sources like a Soil Moisture sensor.

“Therefore, we are very pleased to be able to expand the platform with this application and provide more value to our customers,”, explains 30MHz Head of Product Cor-Jan Holwerda. “30MHz is a platform where all the data and knowledge from growers and from consultants and suppliers in the industry become connected. It’s a central platform to visualise, combine, store and share all your data and convert them into actionable insights.”

Want to know more about this app and the 30MHz platform? Fill in this form to request more information.

Watch our webinar with Olivier of 2Grow:

Together with biotechnology company 2Grow we developed a new application: 2Grow Plant Insights. This app provides growers, breeders and researchers with even more detailed insights into the health and needs of their plants. Read more: https://t.co/NTy7n6USjn

— 30MHz (@30mhz) December 11, 2020

Timo Spruijt is 30MHz’s new CCO: ‘Together with growers and partners we innovate’

Timo Spruijt is 30MHz’s new Chief Commercial Officer (CCO). Together with 30MHz Timo wants to take big steps in innovating agriculture and simplify digitalisation in the sector. “Growers and partners can use 30MHz to decide which information is valuable to their business.”

Ever since he was young Timo Spruijt worked in agriculture. A sector that brought him all over the world. When he was 13 years old he began fluffing roses and from the age of 17 he is working full time in agriculture. After different jobs for growers and breeders he started working for Koppert Biological Systems as an international high tech-consultant 12 years ago. He moved to Mexico to become Kopperts commercial officer and stayed there for a few years. Then he returned to the head office in the Netherlands where he started working as a commercial manager in the Agri Division.

“In that role I translated the technological aspects of the products to a pragmatic story for the customer”, Timo says. “While doing that I continuously kept the customers wishes and expectations in mind. I believe that everything you do in a business has to be aimed at your customers and that they will tell each other that you are the right company for them.”

Now you landed at the digital side of agriculture. Why did you join 30MHz?

“I want to innovate. Technological innovation is a huge trend and has a major influence on agriculture. When I talked to 30MHz it all came together. This company has a unique and strong position which convinced me that I had to do it. Last year I started a global executive Master of Business Administration (MBA). In the first week we had to prepare a personal statement. I said: ‘I will innovate agriculture’. At 30MHz I will get the chance to do just that.”

What are your thoughts on technological innovation in agriculture?

“Agriculture is known for its ‘fingerspitzengefühl’ and the will to innovate continuously. The growers know what is most important for their crops and their business. By monitoring and automating growers can get the maximum out of their knowledge and experience, and their suppliers. But if you get overwhelmed with all the new developments, it can be hard to process the information into something that improves your business.”

What role is 30MHz playing in all this?

“As I said: the grower knows what’s best for their business. 30MHz can simplify things for them by translating digitalization to practical information. We see that growers have lots of equipment, information from different sources and get advice from different companies. That can be difficult. We ask the growers: ‘What do you want to know and what do you want to learn?’ Well by using the 30MHz platform you can see just that. 30MHz doesn’t take sides and the platform evolves together with the growers and their partners. The partners of growers are our partners and we would like to connect their future systems to our platform. The grower decides what is valuable and which information he needs. He is in control and decides who can see his data. On the other end there are partners that offer their data on the 30MHz platform. This way they can provide solutions for growers who have more complex questions. Together we innovate the sector.”

What are your views and plans for the future?

“30MHz is not just a platform for existing features, but also for the coming aspects. The development of precision growing, drones and robots combined with the public demand for a more transparent and responsible way of growing, will create a wave of information in agriculture. 30MHz is able to support this in real time. Not in the form of an overwhelming wave of information, but a summary that is relevant to you. This way 30MHz can be the centre of knowledge sharing, while the growers and their partners keep developing in their own field. It is my dream to help growers on all continents to implement this innovation and to transfer knowledge into action. Together with them I want to make a difference. To get back on my earlier statement: ‘I will innovate agriculture’, starting at 30MHz is the first step in that mission.”

Timo Spruijt is 30MHz’s new Chief Commercial Officer. Together with 30MHz Timo wants to take big steps in innovating agriculture and simplify digitalization in the sector. Welcome Timo! Read more about his mission: https://t.co/QBR5eEL6bC pic.twitter.com/Agvv7GWS0D

— 30MHz (@30mhz) December 4, 2020